Brake Beaver

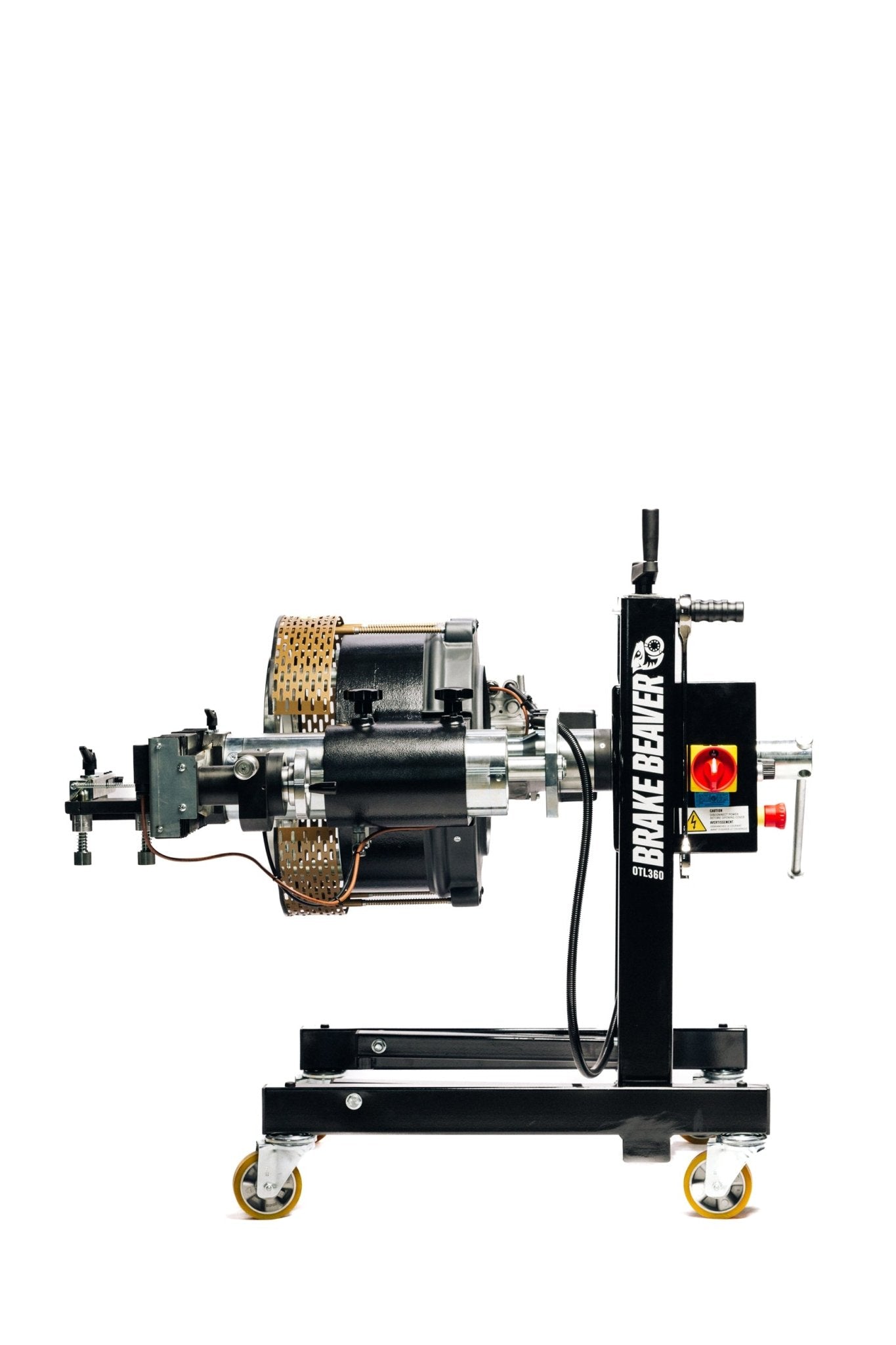

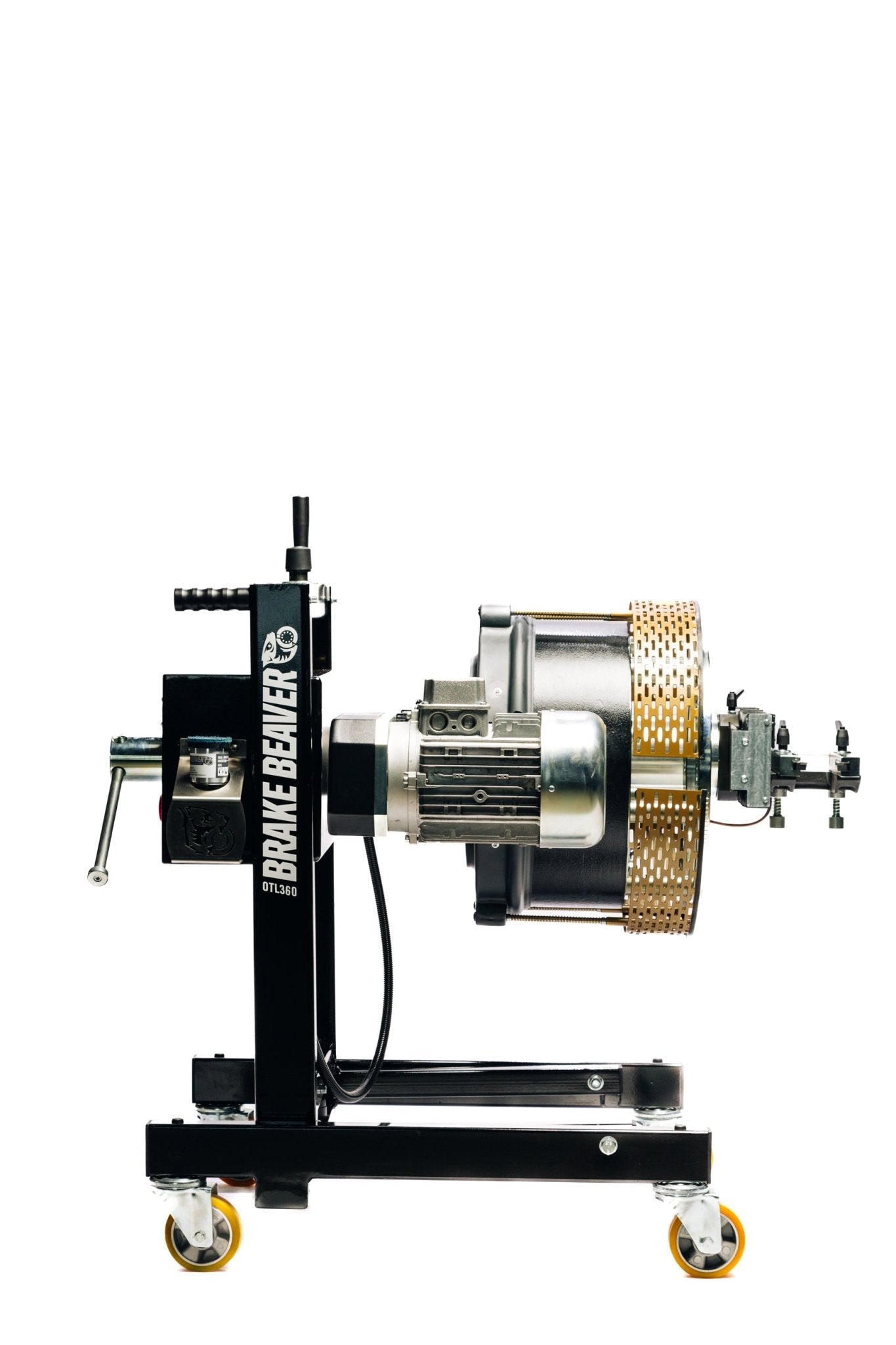

Brake Beaver OTL-360

Brake Beaver OTL-360

Couldn't load pickup availability

What tools are available to resurface Air Disk Brakes on my Truck, Trailer, Bus?

Brake Beaver OTL-360. It's designed for heavy duty, on-the-vehicle brake disc resurfacing which saves thousands of dollars in costs, increases productivity, and makes your business or fleet more profitable.

Contact Us to demo at your location

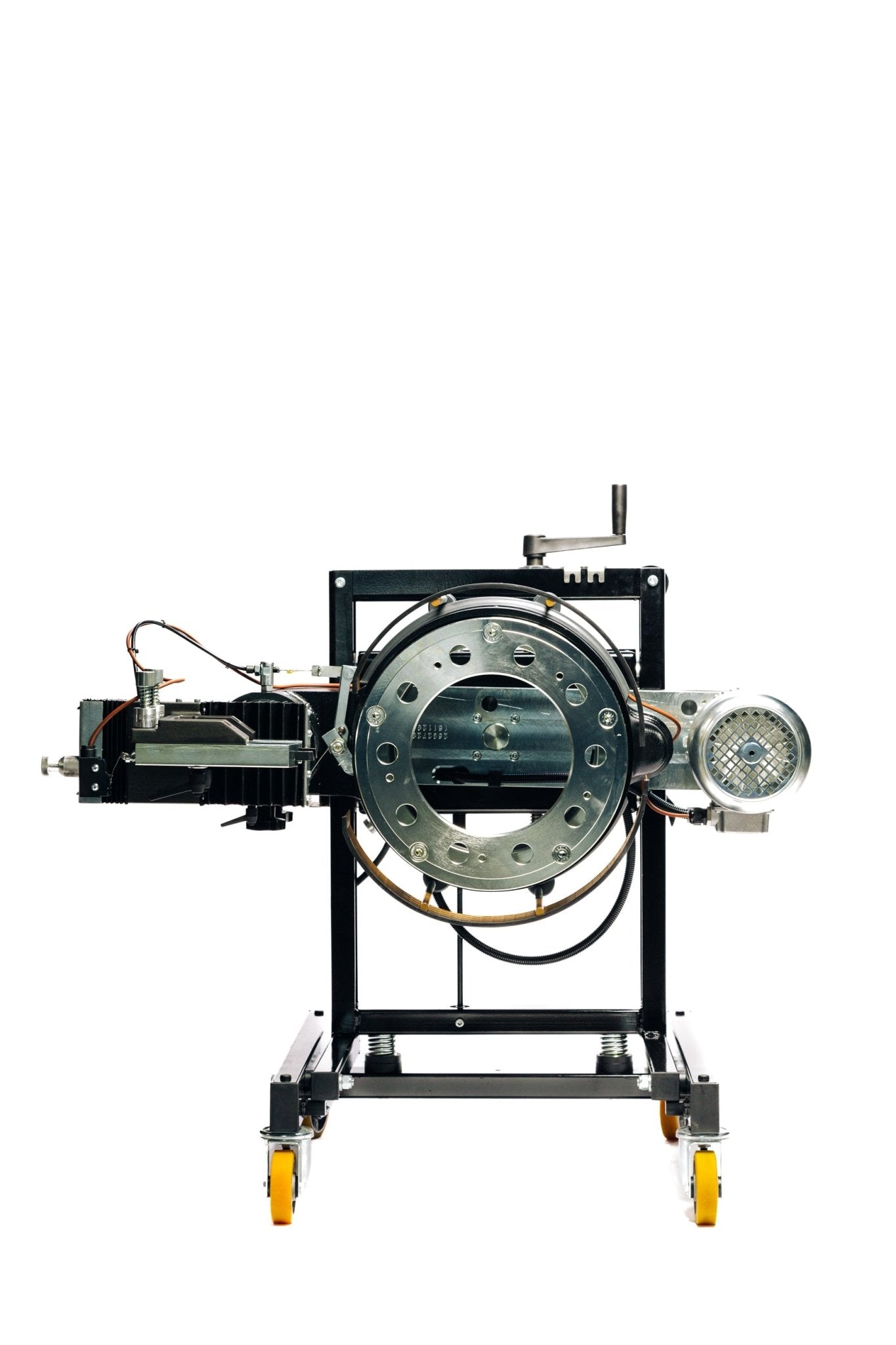

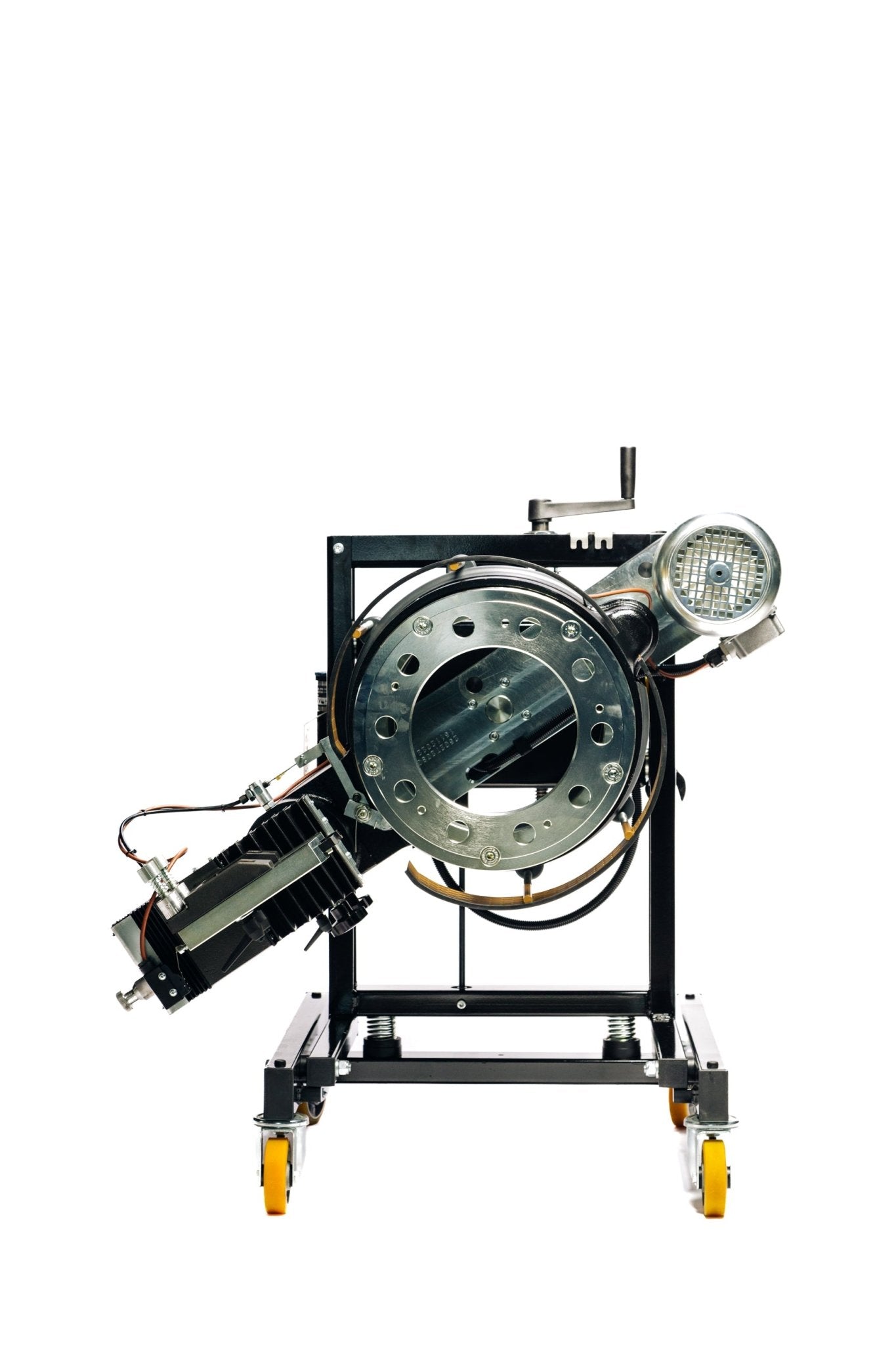

This on-the-vehicle lathe is designed for trucks, trailers, buses and other heavy-duty applications equipped with disc brakes.

1. Precision and Accuracy

One of the primary benefits of the OTL-360 Brake Beaver is its ability to provide high-precision resurfacing. It ensures that brake rotors and drums are resurfaced to exact specifications, which is crucial for proper brake performance. Accurate resurfacing helps in restoring the rotor's friction surface to optimal condition, ensuring smoother braking and extending the life of both the brake pads and rotors.

2. Efficiency in Heavy-Duty Applications

The OTL-360 is specifically designed for heavy-duty applications, making it ideal for resurfacing large brake components like those used in semi-trucks, buses, and other commercial vehicles. Its robust build and capabilities allow it to handle the larger size and weight of heavy-duty rotors and drums that are typically challenging to work with on standard lathes.

3. Versatility

The OTL-360 Brake Beaver is versatile and can be used to resurface not only brake rotors but also brake drums. This versatility allows it to be a one-stop solution for a variety of brake resurfacing needs. Whether you're working with disc brakes or drum brakes, the OTL-360 is capable of delivering consistent results for both types of components.

4. Ease of Use

The OTL-360 is designed with user-friendliness in mind. It features an intuitive control panel and ergonomic design, making it easier for technicians to operate and reduce the learning curve. The simplicity of operation ensures that brake resurfacing is done efficiently and with minimal error, which is essential in busy workshops.

5. Enhanced Brake Performance

By resurfacing brake components to a smooth, even surface, the OTL-360 Brake Beaver improves brake performance. Proper resurfacing helps restore the contact between the brake pads and rotors, which in turn enhances braking efficiency. It also reduces brake noise, vibration, and uneven wear, which can result from improper surface conditions on brake components.

6. Durability and Longevity

The OTL-360 Brake Beaver is built with heavy-duty construction, ensuring that it can handle the demanding environment of commercial vehicle brake maintenance. Its sturdy design means it can withstand the wear and tear of constant use in high-volume repair shops, contributing to a longer lifespan for the machine itself.

7. Minimizes Downtime

Resurfacing with the OTL-360 is quicker and more efficient than traditional methods, reducing downtime for vehicles that need brake maintenance. In industries where time is of the essence, especially for fleet operators and commercial vehicle owners, minimizing downtime is crucial for maintaining operational efficiency and reducing costs associated with delayed repairs.

8. Cost-Effectiveness

By using the OTL-360 Brake Beaver, businesses can save money by resurfacing brake rotors and drums rather than replacing them. This is particularly important for commercial vehicles, where brake components are large and costly to replace. Resurfacing can extend the life of these components, providing a more cost-effective alternative to replacement without sacrificing performance.

9. Improved Safety

Properly resurfaced brake components are essential for maintaining the safety of commercial vehicles. The OTL-360 Brake Beaver ensures that brake rotors and drums are resurfaced to the necessary specifications, preventing issues like brake fade, uneven pad wear, or vibrations. This results in safer braking performance, reducing the likelihood of accidents due to brake failure.

10. Reduced Environmental Impact

By resurfacing brake components rather than replacing them, the OTL-360 can contribute to a reduction in waste. Reusing parts through resurfacing is an environmentally friendly practice, as it minimizes the number of rotors and drums that need to be disposed of, supporting sustainability efforts within the industry.

Share